Description

Well cut cores are the basic condition for a smooth production and winding process. Our automatic core cutting machines incorporate years of experience and continuous improvements to reduce the physical effort of your employees and time costs to a minimum.

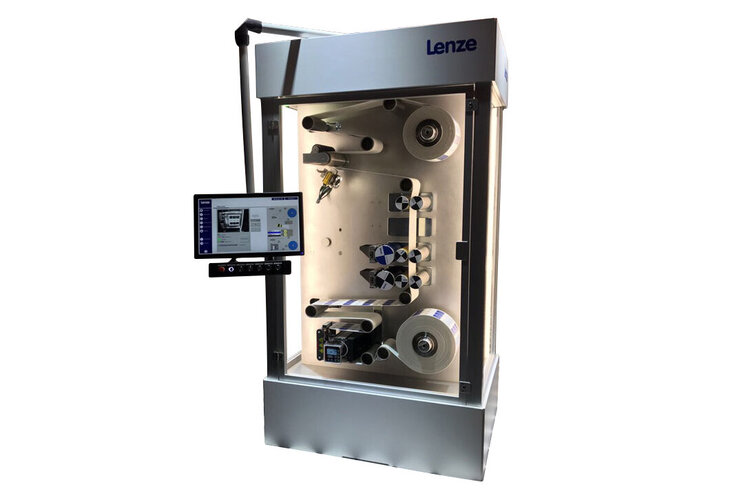

A robust, uncompromising design combined with the latest control technology “Made in Germany” rounds off the concept. All parameters can be entered via a touch panel, and the operating elements for the most important steps are always within reach of the operator (e.g. feeding the cores).

The core cutter has, optionally, a free-running or driven core knife. By means of a servo drive, a wide range of cutting widths can be programmed and are automatically run off. A complete enclosure provides maximum protection for your employees and also reduces dust and noise pollution in the working area.

If you have any questions about your future core cutter or special requirements, please feel free to contact us and our team will work with you to find the best possible solution for you.

Technical Data

| Print width | Max. up to 2000 mm (larger on request) |

| Light sensor scan of core ends during operation | |

| Self-developed Vibration Stop prevents the rocking in the cutting process | |

| Better replacement of cores, due to the special supported main shaft | |

| Machine operation | Control panel / manually by control switch |

| Drive of the servo motors by a PLC | |

| Roller diameter | Min. 25 mm / max. 152 mm |